Preassembled Stairs

From the simple to the extraordinary. . . our staff of experienced stair builders will prove invaluable in planning and constructing your preassembled stair.

The preassembled staircase has long been considered the most efficient method of stair building for larger projects and production markets. Its advantages of fast, accurate installation and job site labor savings are well known. Cooper Stairworks’ stairs combine additional enhancements, adding still more advantages over site-built stairs and exceeding the quality expectations of the most discerning craftsman.

Prefit Rail Systems

Cooper Prefit Rail Systems combined with our Preassembled Stairs enable you to realize many cost efficiencies. No more questioning which parts to use, where to find them, or how they go together; simply select any stock or custom balustrade and our professional stair builders will configure the correct parts and prefit them to your stair while it is in our shop.

For CAD drawings of stair layouts and stair parts, visit our CAD Stair Library.

View or Download the Preassembled Stairs Brochure

From the simple to the extraordinary…

Whether you need a simple and safe utility stair to the cellar, a rail system, or an aesthetic balance of curves from floor to balcony in a larger foyer, our staff of experienced stair builders will prove invaluable in time saving service.

Our goal is to make it easy for you every step of the way. Beginning with the basic elements: treads, risers and rail systems, we will help you determine the best layout for your home. We will take into account all of your design parameters and with our many years of experience, provide you with a completely coordinated stair and rail system to meet your particular desires.

Building Codes

A Cooper preassembled staircase is not only beautiful, it is safe. Part of the design process is understanding various building codes in the different states and being able to educate our customers. The rise and run are two of the most important variables in determining the space necessary for the stair. In addition, the handrail and balusters provide support and prevent falls. A Cooper Stairworks expert can help guide you through the intricacies of baluster spacing, handrail graspability, and headroom.

Our goal is to make it easy for you every step of the way. Beginning with the basic elements – treads, risers and rail systems – we will help you determine the best layout for your home. We will take into account all of your design parameters and with our many years of experience, provide you with a completely coordinated stair and rail system to meet your particular desires.

View or Download the Preassembled Stairs Brochure

Field Measurement

In our direct service area, our techs field measure the job completely, make recommendations as needed, and work with a Project Manager from beginning to end.

CAD Support

Not all stair projects require CAD support, but when necessary we provide very detailed drawings of the project for review.

State-of-the-Art Technology

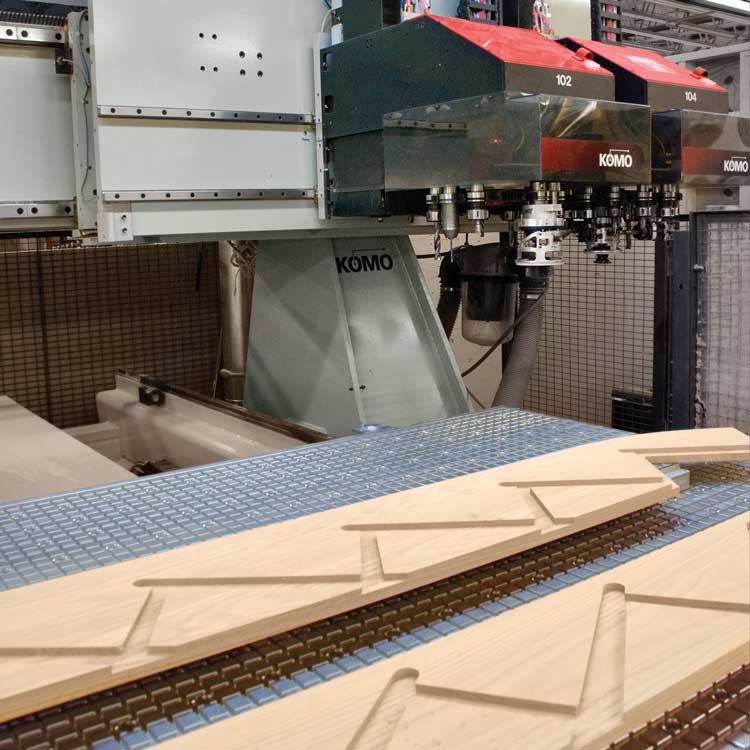

We have invested in the latest technology available. Automatic stair design software is used to support two CNC routers with 4 and 5 axis machining capabilities.

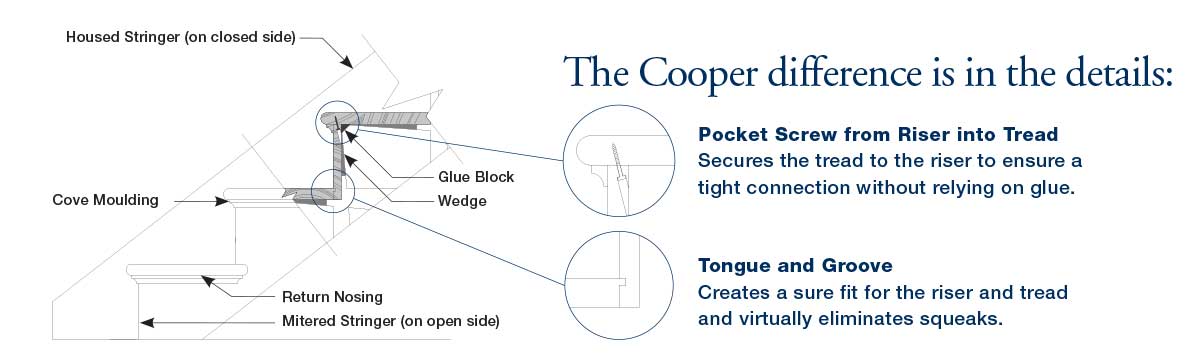

Tongue & Groove Construction

This superior method of assembly creates a sure fit for the riser to the tread and virtually eliminates squeaks.

Notched Newels

With our prefit rail system, all newels are notched to the proper height to comply with code in conjunction with the rail system. They are dry fitted and marked for location.

ZIPBOLT™ UT Rail Bolt

All our rail joint connections are made using the ZIPBOLT™ UT Rail bolt. Easier, faster, and stronger. Tighten joints in seconds.

Threaded Inserts

On wooden, turned, tapered-top balusters, we use a threaded insert in the tread and a machine/lag screw in the baluster for superior strength and ease of installation.

Fas-n-Fast

A strong machine screw style connector is used to connect all pin bottom newels to the starting step.

Blind Fasteners

When we apply a return to a stair tread, all work is done on the backside so fasteners are never visible on the finish face and edge of the tread.

Packaging

The stair is wrapped in clear plastic with custom water resistant double thick cardboard tread and riser guards applied for protection during construction.

Plywood Templates

Plates are provided for framing balcony sections and supporting walls. Stairs are assembled back in our shop using exact duplicates of these templates.

Easy Installation

As soon as the project is weather tight, the stair is normally installed in less than half a day so it can be used during the construction process.

All stair parts are made at our factory (unless otherwise noted) and are available in the species below. When your project requires a specific species not shown, let us call on our lumber suppliers from all over the globe to find it.

Sapele and Utile Mahogany

Sapele and Utile are very similar to Honduras Mahogany with a regular striped pattern and a dark red-brown color. This species sands and finishes easily and smoothly. Sapele is used for Paint Grade and Utile is used for Stain Grade.

Red Oak

Red Oak features a very strong grain pattern which ranges from fine, straight, and close to spread and pronounced. Red Oak stains well for an excellent finish.

White Oak/Quarter Sawn White Oak

White Oak is primarily warm in color with a hint of ash. It’s grain pattern varies from straight and tight to arched and dramatic. White Oak stains well for an excellent finish. White Oak is used for Stain Grade and Quarter Sawn White Oak is used for Paint Grade.

Eastern White Pine

This softwood is light brown in color, often with a reddish tinge and turns darker on exposure to air. Eastern White Pine features a comparatively uniform texture and is straight grained.

Maple

Maple is strong and hard with a uniform color, texture, and grain. It sometimes features areas with dark streaks and birds-eye or worm track patterns. If left clear, maple may yellow with age.

Cherry

Cherry is characterized by its warm color, smooth texture and straight, fine, and tight grain. Cherry may contain some sapwood and/or pin knots and will darken over time.

Poplar

This hardwood is light in color and may feature dramatic dark color variations. Poplar is mostly painted or used with dark stains.

Walnut

Walnut is characterized by its beautiful grain lines running throughout and its dark brown color. Walnut veneers may be laminated for width and contain some sap grain and pin knots.

Reclaimed Wood

Reclaimed wood is seasoned lumber that has been salvaged from abandoned barns, factories and industrial buildings. Some common types are: pine, elm, cherry, chestnut, walnut, hickory, maple, and quartersawn oak.

Jatoba

Also called Brazilian Cherry, this hardword has warm undertones and finishes and stains well.